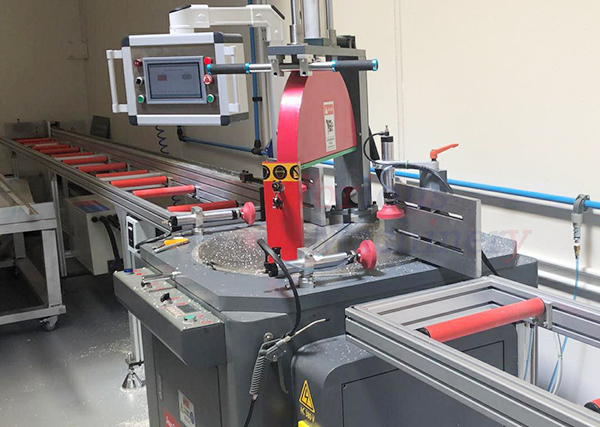

滾壓復(fù)合機(jī)在多個(gè)工業(yè)領(lǐng)域發(fā)揮著關(guān)鍵作用,其工作原理基于機(jī)械力、壓力及材料特性的協(xié)同作用,以實(shí)現(xiàn)不同材料的復(fù)合加工。不同類型的滾壓復(fù)合機(jī)因應(yīng)用場(chǎng)景不同,工作原理存在一定差異,以下以常見(jiàn)的金屬板材滾壓復(fù)合機(jī)和管材滾壓復(fù)合機(jī)為例進(jìn)行介紹。

The rolling composite machine plays a key role in multiple industrial fields, and its working principle is based on the synergistic effect of mechanical force, pressure, and material characteristics to achieve composite processing of different materials. Different types of rolling composite machines have certain differences in their working principles due to different application scenarios. The following will introduce common metal sheet rolling composite machines and pipe rolling composite machines as examples.

金屬板材滾壓復(fù)合機(jī)工作原理

Working principle of metal sheet rolling composite machine

送料系統(tǒng)運(yùn)作:在金屬板材滾壓復(fù)合的起始階段,送料系統(tǒng)承擔(dān)著重要職責(zé)。該系統(tǒng)通常由電機(jī)驅(qū)動(dòng)的輥輪組構(gòu)成,其運(yùn)轉(zhuǎn)速度可依據(jù)加工工藝要求進(jìn)行精準(zhǔn)調(diào)控。金屬板材被放置于送料臺(tái)上,在輥輪的摩擦力作用下,板材被平穩(wěn)且勻速地送入滾壓復(fù)合區(qū)域。送料的精準(zhǔn)度和穩(wěn)定性對(duì)復(fù)合質(zhì)量影響重大,若送料速度不均勻,會(huì)導(dǎo)致復(fù)合后的板材出現(xiàn)厚度不均、貼合不緊密等問(wèn)題。例如,在汽車(chē)制造中用于生產(chǎn)車(chē)身覆蓋件的滾壓復(fù)合機(jī),送料系統(tǒng)需將不同材質(zhì)的金屬薄板精確地送入,確保后續(xù)復(fù)合工序順利進(jìn)行。

The operation of the feeding system: In the initial stage of metal sheet rolling composite, the feeding system plays an important role. This system is usually composed of a roller set driven by a motor, and its operating speed can be precisely controlled according to the processing requirements. The metal sheet is placed on the feeding platform, and under the frictional force of the rollers, the sheet is smoothly and uniformly fed into the rolling composite area. The precision and stability of feeding have a significant impact on the quality of composite materials. If the feeding speed is uneven, it can lead to uneven thickness and loose bonding of the composite board. For example, in the production of car body coverings using a rolling laminating machine, the feeding system needs to accurately feed metal sheets of different materials to ensure the smooth progress of subsequent laminating processes.

滾壓成型過(guò)程:當(dāng)金屬板材進(jìn)入滾壓復(fù)合區(qū)域后,會(huì)遭遇一系列經(jīng)過(guò)特殊設(shè)計(jì)的滾壓模具。這些模具一般成對(duì)設(shè)置,且表面具有特定的形狀和紋理。上下模具在電機(jī)通過(guò)傳動(dòng)裝置提供的動(dòng)力驅(qū)動(dòng)下,以相反方向高速旋轉(zhuǎn)。在旋轉(zhuǎn)過(guò)程中,模具對(duì)板材施加強(qiáng)大的壓力和摩擦力。壓力促使板材發(fā)生塑性變形,而摩擦力則帶動(dòng)板材在模具間移動(dòng)。通過(guò)多組不同形狀模具的依次滾壓,板材逐漸被加工成預(yù)定的形狀。以生產(chǎn)波紋狀金屬?gòu)?fù)合板為例,滾壓模具表面設(shè)計(jì)有與波紋形狀對(duì)應(yīng)的凹槽和凸起,在滾壓過(guò)程中,板材在模具作用下形成規(guī)則的波紋結(jié)構(gòu),同時(shí)不同金屬層在壓力作用下緊密貼合,實(shí)現(xiàn)復(fù)合。

Rolling forming process: When the metal sheet enters the rolling composite area, it will encounter a series of specially designed rolling molds. These molds are usually set up in pairs and have specific shapes and textures on their surfaces. The upper and lower molds rotate at high speed in opposite directions under the power provided by the motor through the transmission device. During the rotation process, the mold exerts strong pressure and friction on the sheet metal. Pressure causes plastic deformation of the sheet, while friction drives the sheet to move between the molds. By sequentially rolling multiple sets of molds with different shapes, the sheet is gradually processed into the predetermined shape. Taking the production of corrugated metal composite plates as an example, the surface of the rolling mold is designed with grooves and protrusions corresponding to the corrugated shape. During the rolling process, the plate forms a regular corrugated structure under the action of the mold, and different metal layers are tightly adhered under pressure to achieve composite.

復(fù)合原理機(jī)制:金屬板材滾壓復(fù)合機(jī)實(shí)現(xiàn)復(fù)合的核心在于壓力和材料特性的相互作用。在滾壓過(guò)程中,強(qiáng)大的壓力使得不同金屬板材的原子間距離減小,當(dāng)達(dá)到一定程度時(shí),原子間產(chǎn)生相互吸引力,從而形成冶金結(jié)合,實(shí)現(xiàn)真正的復(fù)合。為增強(qiáng)復(fù)合效果,有時(shí)會(huì)在復(fù)合前對(duì)板材表面進(jìn)行預(yù)處理,如清潔、打磨,以去除表面的氧化層和雜質(zhì),使板材表面更潔凈,利于原子間結(jié)合。此外,還可通過(guò)控制滾壓溫度來(lái)輔助復(fù)合,在一些特殊金屬材料的復(fù)合中,適當(dāng)升高溫度可提高原子的活性,促進(jìn)原子擴(kuò)散,進(jìn)一步加強(qiáng)復(fù)合強(qiáng)度。

Composite principle mechanism: The core of metal sheet rolling composite machine to achieve composite lies in the interaction between pressure and material properties. During the rolling process, strong pressure reduces the distance between atoms of different metal sheets. When it reaches a certain level, mutual attraction is generated between atoms, forming metallurgical bonding and achieving true composite. To enhance the composite effect, sometimes the surface of the board is pre treated before composite, such as cleaning and polishing, to remove the oxide layer and impurities on the surface, making the board surface cleaner and conducive to interatomic bonding. In addition, the composite can be assisted by controlling the rolling temperature. In the composite of some special metal materials, increasing the temperature appropriately can improve the activity of atoms, promote atomic diffusion, and further enhance the composite strength.

您當(dāng)前所在位置:

您當(dāng)前所在位置:

TEL:18678805065

TEL:18678805065 ADD:山東省濟(jì)南市市中區(qū)經(jīng)十西路6288-2號(hào)

ADD:山東省濟(jì)南市市中區(qū)經(jīng)十西路6288-2號(hào) 濟(jì)南歌德瑞斯機(jī)械設(shè)備有限公司

濟(jì)南歌德瑞斯機(jī)械設(shè)備有限公司 備案號(hào):

備案號(hào):

技術(shù)支持:

技術(shù)支持: